When it comes to research, product testing, or manufacturing, one of the most critical factors that often goes unnoticed is humidity. Moisture levels—whether too high or too low—can significantly impact a product’s stability, performance, and overall quality. This is where a humidity control oven—also commonly referred to as a humidity oven—plays a vital role.

In this article, we’ll explore what a humidity control oven is, why it’s important, and the science behind how it works.

What is a Humidity Control Oven?

A humidity oven (sometimes called a climatic chamber or environmental chamber) is a specialized piece of equipment designed to regulate both temperature and humidity within a controlled chamber.

Unlike standard ovens, which only provide heating, a humidity control oven allows users to simulate real-world environmental conditions—from dry desert-like settings to highly humid tropical climates.

This makes them essential for industries such as:

- Pharmaceuticals – drug stability testing

- Food & Beverages – shelf-life and packaging studies

- Electronics – moisture resistance testing

- Aerospace & Automotive – material durability under varying climates

- Research Laboratories – controlled experiments

Why Humidity Control Matters

Moisture levels have a significant influence on materials, products, and biological specimens in various ways:

- Metals may corrode faster in high humidity.

- Electronics can short-circuit due to condensation.

- Medicines can degrade in strength when subjected to high moisture levels.

- Food products may spoil or lose texture.

By recreating these conditions in a humidity oven, companies can test, validate, and improve product performance before releasing them to the market.

How Does a Humidity Control Oven Work?

A humidity control oven is essentially an environmental simulation system that combines temperature conditioning, humidity generation, precise sensors, and intelligent control algorithms. The goal is to reproduce consistent climatic conditions for testing or processing.

Here’s a deeper look at how it works:

1. Temperature Regulation System

Heating: Electrical heating elements (usually resistive heaters) raise the chamber’s temperature.

Cooling: A refrigeration system (compressor, condenser, evaporator) or Peltier-based thermoelectric modules lowers the temperature when needed.

Thermal Uniformity: Insulated stainless-steel chambers combined with forced-air circulation prevent temperature gradients.

Control Range: Most humidity ovens can operate from sub-zero conditions (e.g., -20°C) up to high heat (~150–200°C), depending on the model.

2. Humidity Generation and Control

Humidification:

- Steam Injection: Water is boiled and introduced as vapor for high-humidity conditions.

- Ultrasonic Atomization: Water is broken into fine mist using ultrasonic waves for controlled humidification.

Dehumidification: Cooling coils condense moisture from the air when lower humidity is required. In advanced models, desiccant systems or molecular sieves are used to absorb moisture.

Reservoir & Purity: Deionized or distilled water is often used to prevent mineral build-up in the system.

3. Sensors, Calibration and Maintenance

Temperature Sensors: Precision thermocouples or RTDs (Resistance Temperature Detectors) provide continuous temperature readings.

Humidity Sensors:

- Capacitive Sensors measure changes in dielectric constant due to water vapor.

- Psychrometric Sensors (wet-bulb/dry-bulb method) are sometimes used for calibration.

Calibration and Maintenance: Regular calibration ensures accuracy and compliance with industry standards, while preventive maintenance—such as cleaning humidifiers, checking seals, and verifying sensor performance—extends oven lifespan and reliability.

Precision: Today’s humidity ovens typically achieve humidity control within ±1–2% RH and temperature stability around ±0.5°C.

4. Air Circulation & Uniformity

Fans and ducting systems distribute conditioned air uniformly across the chamber.

This prevents hot/cold spots or localized moisture variations, ensuring test samples experience the same conditions.

High-end ovens use multi-directional airflow for improved stability during long-duration tests.

5. Control Systems & Automation

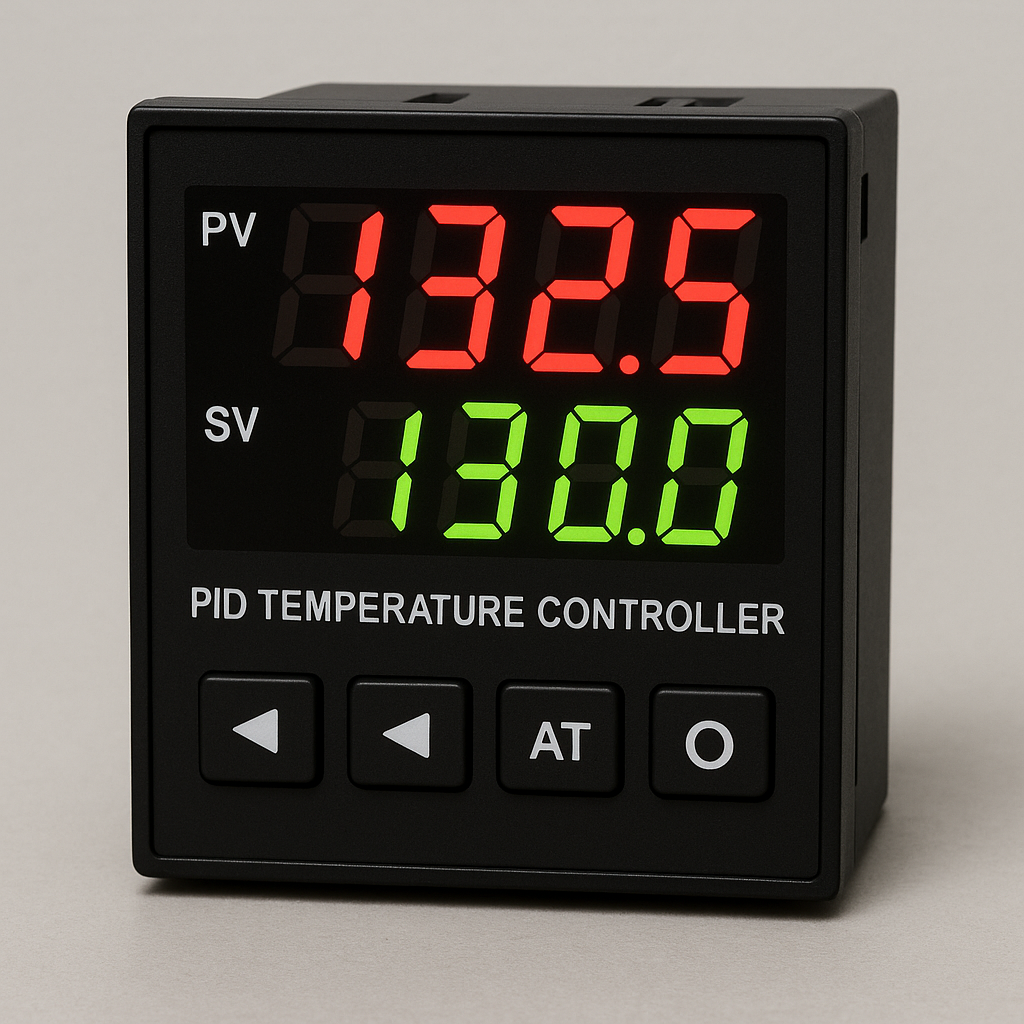

PID Controllers (Proportional–Integral–Derivative): These advanced algorithms continuously adjust heating, cooling, and humidity input to minimize fluctuations.

Touchscreen panels enable users to program temperature and humidity settings, adjust ramp speeds, and define holding periods.

Programmable Profiles: Users can simulate day/night cycles, seasonal shifts, or accelerated aging conditions.

Data Logging & Connectivity: Modern ovens support USB, Ethernet, or Wi-Fi for exporting real-time test data and remote monitoring.

6. Safety & Compliance Features

Over-temperature protection prevents overheating.

In case of a malfunction, automatic valves stop the water supply to prevent damage.

The oven generates alarms to signal any deviation from preset environmental limits.

Many ovens comply with ICH guidelines, FDA requirements, or ISO 9001 standards, making them suitable for regulated industries.

Example: Typical Working Ranges

Most humidity control ovens can simulate conditions such as:

- Temperature Range: -20°C to 150°C

- Humidity Range: 20% RH to 98% RH

These wide ranges allow researchers and manufacturers to replicate nearly any climate on Earth.

Benefits of Using a Humidity Oven

- Reliable Testing: Ensures products can withstand real-world conditions.

- Quality Assurance: Helps meet regulatory standards (e.g., FDA, ICH guidelines).

- Cost Savings: Identifies potential issues before mass production.

- Versatility: One humidity control oven can serve multiple industries and applications.

Real-World Applications

- Pharmaceuticals: Conducting extended stability studies on medicines in compliance with ICH standards.

- Food Industry: Studying mold growth or moisture loss in packaged goods.

- Electronics: Checking circuit boards against humidity-induced failures.

- Materials Testing: Evaluating adhesives, coatings, and plastics under varying conditions.

A humidity oven is more than just lab equipment—it’s a crucial tool for ensuring the safety, durability, and quality of products across industries. By simulating real-world climates, these ovens allow manufacturers and researchers to anticipate challenges, reduce risks, and deliver better results.

Whether you’re in pharmaceuticals, food processing, or electronics, investing in a reliable humidity control oven means investing in trust, compliance, and innovation.