In laboratory environments where precision, repeatability, and versatility are essential, table top jar mills play a crucial role in material preparation. These compact and efficient machines are designed for grinding, mixing, and blending small batches of materials across a wide range of scientific fields. Whether you're working in chemistry, materials science, or pharmaceuticals, a jar mill can significantly enhance your lab’s capabilities.

In this post, we’ll explore the key applications of table top jar mills in modern laboratory settings, highlighting how they contribute to accurate research, formulation, and process development.

1. Sample Grinding and Pulverization

One of the most common uses of a table top jar mill is to grind and pulverize solid samples into fine powders. This process is essential in labs where materials need to be in a uniform particle size for chemical analysis or formulation development.

Why It’s Important:

- Ensures sample homogeneity for analytical consistency.

- Improves the effectiveness of reactions by ensuring more uniform contact between materials.

- Prepares samples for downstream techniques like spectroscopy, thermal analysis, and microscopy.

Examples:

- Geology Labs: Pulverizing rock or soil samples before X-ray fluorescence (XRF) or inductively coupled plasma (ICP) analysis.

- Pharmaceutical R&D: Grinding drug ingredients to optimize solubility and bioavailability.

- Ceramic Labs: Reducing raw materials (e.g., alumina, silica) to powder form before sintering.

2. Homogeneous Mixing of Powders

Achieving a uniform distribution of different components is critical in scientific studies and product development. Table top jar mills allow thorough mixing of fine powders, which is vital in preparing blends that perform consistently in further processing.

Why It’s Important:

- Prevents component segregation, especially in low-dose drug formulations.

- Enhances reproducibility in experimental setups.

- Helps in the optimization of formulations for quality control.

Examples:

- Pharmaceutical Labs: Blending APIs with excipients before tablet compression.

- Materials Science Labs: Combining titanium and graphite powders for sintered composites.

- Additive Manufacturing: Preparing homogenous powder blends for selective laser sintering.

3. Mechanical Alloying and Nanomaterial Synthesis

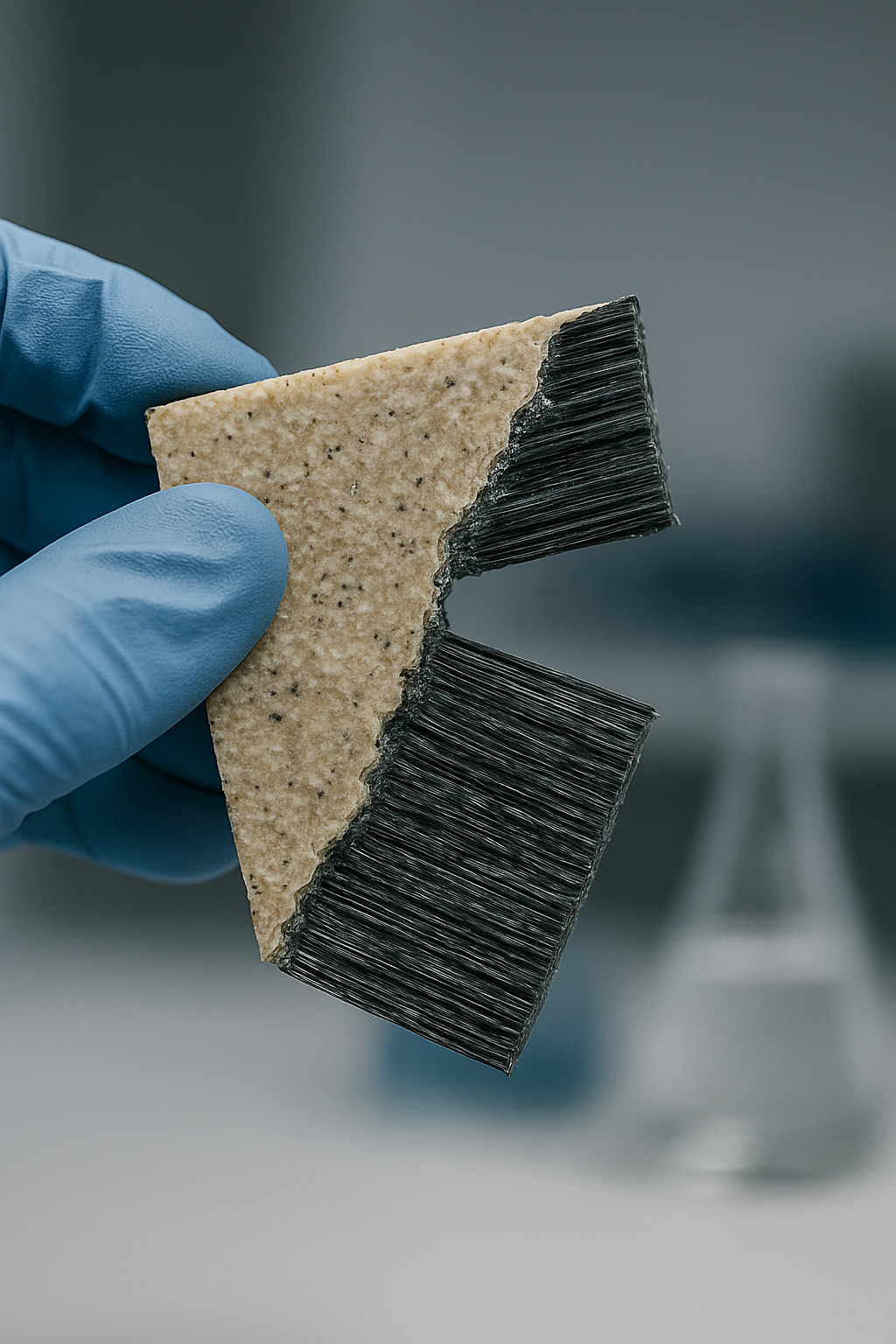

Jar mills support high-energy milling, which is critical for mechanical alloying. This process involves repeated fracturing and cold welding of powder particles to form new alloy phases or nanocomposites.

Why It’s Important:

- Enables synthesis of non-equilibrium structures.

- Useful for nanoparticle production and advanced composites.

- Allows alloying of immiscible elements in a solid state.

Examples:

- Metallurgy Research: Developing custom powder blends such as Al-Ni or Fe-Cu for experimental alloy studies.

- Nanomaterials Labs: Milling graphite with metals to create graphene-metal hybrids.

- Energy Storage: Milling cathode materials for lithium-ion battery research.

4. Wet and Dry Milling for Reaction Preparation

Both wet and dry grinding are supported by table top jar mills, making them suitable for preparing slurries, solvent-based reactions, or dispersion systems. Wet milling is well-suited for materials that degrade at high temperatures or are prone to oxidation during processing.

Why It’s Important:

- Prevents overheating and improves milling efficiency.

- Facilitates solvent-based synthesis or dispersion preparation.

- Helps deagglomerate particles into stable suspensions.

Examples:

- Chemical Synthesis: Pre-milling reactants in ethanol or acetone for sol-gel processes.

- Paint & Ink Formulation: Milling pigments in solvent carriers.

- Battery Material Processing: Preparing anode/cathode slurries.

5. Formulation Testing and Prototyping

Before scaling up to production, R&D labs use small-scale equipment like jar mills to test new formulations. These mills enable rapid iteration and cost-effective prototyping with minimal material usage.

Why It’s Important:

- Reduces waste of expensive materials.

- Supports quick formulation testing.

- Allows for easy optimization and scaling.

Examples:

- Pharmaceutical Development: Preparing pre-compression blends to evaluate compressibility and uniformity.

- Polymer Science: Testing polymer-filler ratios for mechanical property evaluation.

- Ceramics R&D: Experimenting with custom glaze formulas on a lab scale.

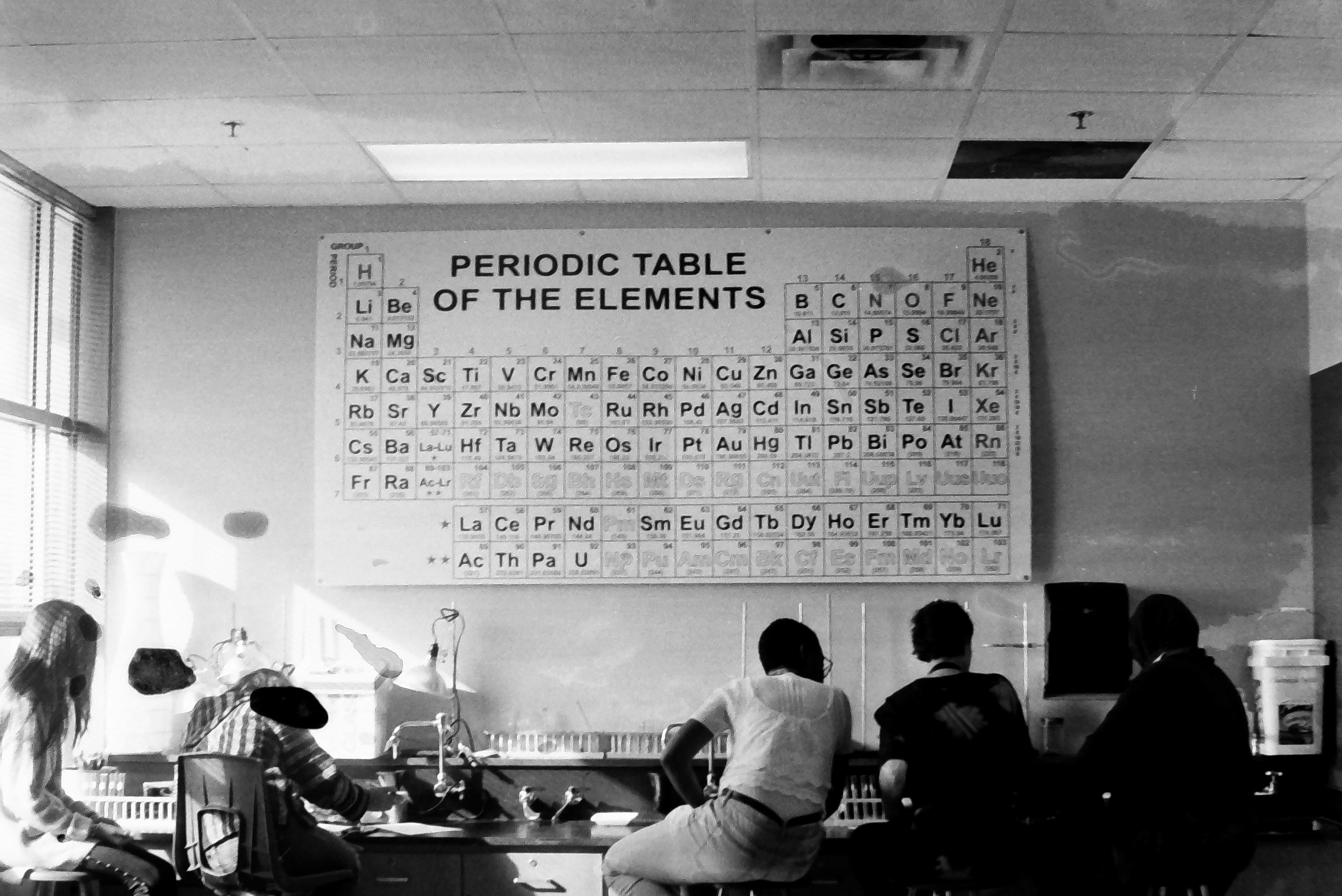

6. Educational Demonstrations and Training

Due to their compact size and ease of use, table top jar mills are excellent teaching tools in academic settings. Instructors use them to demonstrate the principles of particle size reduction, powder blending, and solid-state reactions.

Why It’s Important:

- Gives students direct interaction with functional laboratory-scale milling tools.

- Introduces best practices for safely working with fine particulate substances.

- Illustrates how changes in parameters such as duration, rotation speed, and grinding media affect outcomes.

Examples:

- University Chemistry Labs: Showing how particle size influences the chemical behaviour of powdered substances.

- Engineering Schools: Teaching students about mechanical alloying.

- Pharmacy Training: Showing blend uniformity and granulation techniques.

Table top jar mills are incredibly valuable across a wide range of lab environments. Their ability to grind, mix, and process materials at small scale with high control makes them essential tools in:

- Research and Development

- Quality Control

- Nanotechnology

- Material Science

- Chemical and Pharmaceutical Labs

- Educational Institutions

By using the right jar material and grinding media, and adjusting milling parameters effectively, laboratories can ensure high efficiency and reproducibility in all their milling and mixing tasks. Always select grinding jars and media that match your material chemistry to prevent contamination and extend the life of your equipment.